The Art of Distillation - Where Craft Meets Clarity

Behind every bottle of Panezski lies a journey of precision, patience, and purpose. Our process is steeped in heritage yet guided by innovation - a delicate balance that transforms raw ingredients into something exceptional. This is where the alchemy of craftsmanship becomes attainable luxury.

The Grain - Our Foundation

The finest Australian raw grains are chosen for purity and character. Normally distilleries rely on malted grains, we prefer raw grain for its crisp, clean flavour profile - allowing the true essence of the grain to shine through.

Grinding - The First Transformation

The way we grind defines everything that follows. Our grains are rolled just enough to release the flavour and complexity we strive for. It's a small detail, but one that sets the foundation for the texture and smoothness that Panezski is known for.

Mashing - Turning Starch into Spirit

During mashing, starches within the grain are converted into fermentable sugars - the essential base for fermentation. At Panezski, we use a traditional, almost forgotte technique that yields a more rounded, expressive spirit. It's slower, but the result is worth every moment.

Yeast - The Living Heart

Yeast is where the magic begins. These remarkable microorganisms are responsible for turning sugar into alcohol - and shaping the flavour and aroma of every Panezski spirit. We have carefully selected a distinct yeast strain, creating depth, warmth, and subtle complexity throughout the distillation.

Fermentation - Time, Temperature, and Taste

As fermentation begins, the transformation truly takes hold. Unlike most distilleries, we ferment on the grain, allowing natural flavours to infuse every stage of the process. Careful control of time and temperature ensures a spirit that's rich, balanced, and remarkably smooth.

The Stripping Run - Extracting the Essence

The first distillation - known as the stripping run - extracts alcohol from the fermented wash. We run our still with intention, gradually capturing the heart of the spirit and preserving its integrity. This phase is about removing impurities while keeping the character that defines Panezski.

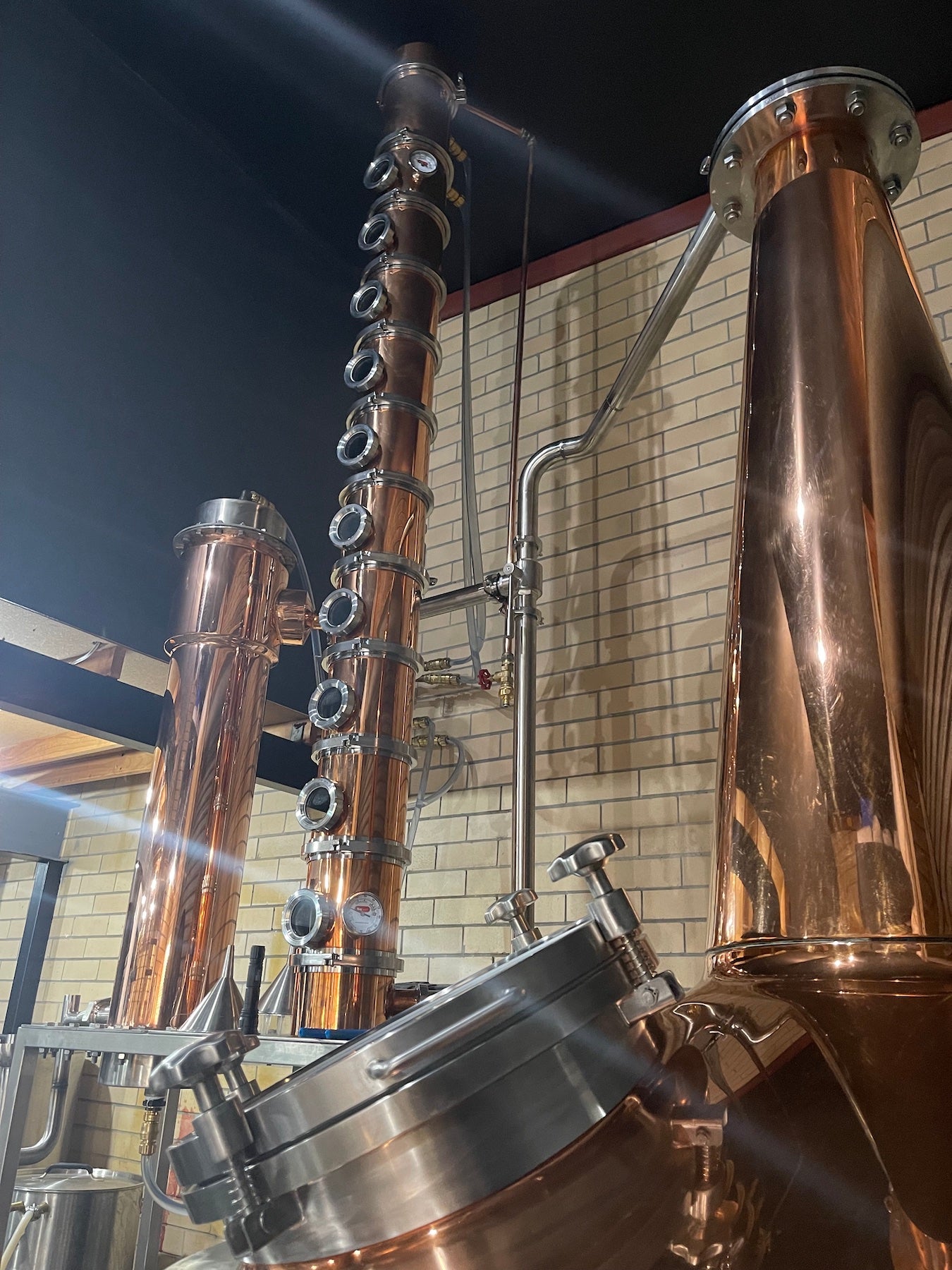

Spirit Run- Refining Perfection

This is where science becomes art. The vapour rises slowly through the still's column, passing through multiple stages of refinement. Each plate in the column acts as another layer of purity, and control. We collect the spirit in small, measured cuts - around 400ml at a time - to ensure only the finest quality is kept for bottling.

Finishing - The Panezski Way

Here, we diverge from convention. While many distilleries rely on carbon filtration to "smooth" their spirits, we believe it strips away character. Instead, we focus on crafting purity through process - by perfecting every stage of distillation. Our vodka retains the delicate, grain-born flavour that makes it truly distinct: subtle, refined, and effortlessly smooth.

This is how it once was done - and how, at Panezski, it still should be.